Subsystems Overview

Husky Robotics is divided into five subsystem engineering teams that work together every year to design, manufacture, and test our rover from the ground up.

Chassis

The chassis subsystem creates a vehicle capable of travelling over the rough terrain of the Martian (Utah) surface while providing stable mounting points for the arm and science station. This team works extensively with Computer Aided Design (CAD) software to create a digital rendering of the rover during fall quarter, selecting parts and consulting with the other subsystems to have the design ready to build in winter. During winter quarter, the chassis subsystem members primarily work to manufacture the base of the rover. Spring quarter is devoted to mechanical fine-tuning, creation of spare parts, and maintenance practice with for competition.

Weekly Time Commitment: About to 8-12 hours

Arm

The arm subsystem is responsible for the design and construction of the chassis-mounted rover arm module. The arm must be capable of lifting up to 5 kg, and should be dexterous enough to pick up tools, perform actions on a control panel, and type on a keyboard. Members of this subsystem learn to design with CAD programs, use the machine shop to manufacture parts, and perform maintenance. The arm subsystem works closely with the software subsystem to develop inverse kinematic control algorithms for ergonomic control of the arm and claw, and with the electronics subsystem to ensure clear paths for wires and sufficient connection durability.

Weekly Time Commitment: About 8-10 hours

Science

The science subsystem is responsible for designing and building the Science Station, a module for the rover that collects and analyzes soil samples as part of the science task. Explicitly, the science station is required to provide information about soil temperature and water content, but the team also chooses other relevant sensors, such as UV exposure and on-board microscope help during site selection and the presentation. The team also chooses and develops a set of off-rover tests such as X-ray spectroscopy, free amine Ninhydrin tests, and pH. The science subsystem needs members capable of CAD modelling, part manufacturing, extensive electronic and software design, and doing background research in astrogeology and astrobiology. It's a great subsystem to join to get a bit of experience in every field of robotics.

Weekly Time Commitment: 8-10 Hours

Electronics

The electrical subsystem designs the hardware and that runs motors and sensors on the rover. The subsystem also designs the power distribution system and creates mathematical models of power consumption and manages the batteries that power the rover. Typical work for an electrical member includes designing printed circuit boards with EagleCAD, soldering, wire management, testing motor control interfaces, and helping software perform debugging. The electrical subsystem works closely with the software subsystem to create a system architecture design for appropriate control of the rover and its systems.

Weekly Time Commitment: 5-10+ Hours

Software

The software subsystem creates the brains of the rover, allowing it to be operated when it is out of sight of the driver. The software subsystem works with drive algorithms, inverse kinematics, artificial intelligence, and interfacing with different controllers to make sure the rover operates quickly and intuitively for the driver. The subsystem also creates the user interface used to drive the rover including camera feeds, on screen controls for precision based operations such as working with the science system, and map based coordinate plotting.

Weekly Time Commitment: 6-12 Hours

Business

The Business team ensures the continuity of Husky Robotics. In charge of raising funds and managing the budget, business team members need to understand the needs of each subsystem and work with the leads to get all necessary parts ordered and delivered in a timely manner. The business team members also present Husky Robotics to the UW and external organizations, corporations, and media outlets, creating content to promote the team, seek sponsorships & outreach opportunities, and try to assist team members in finding internships.

Business team members are encouraged to join other subsystems to learn more about Husky Robotics.

Weekly Time Commitment: 2-3 hours

Manufacturing

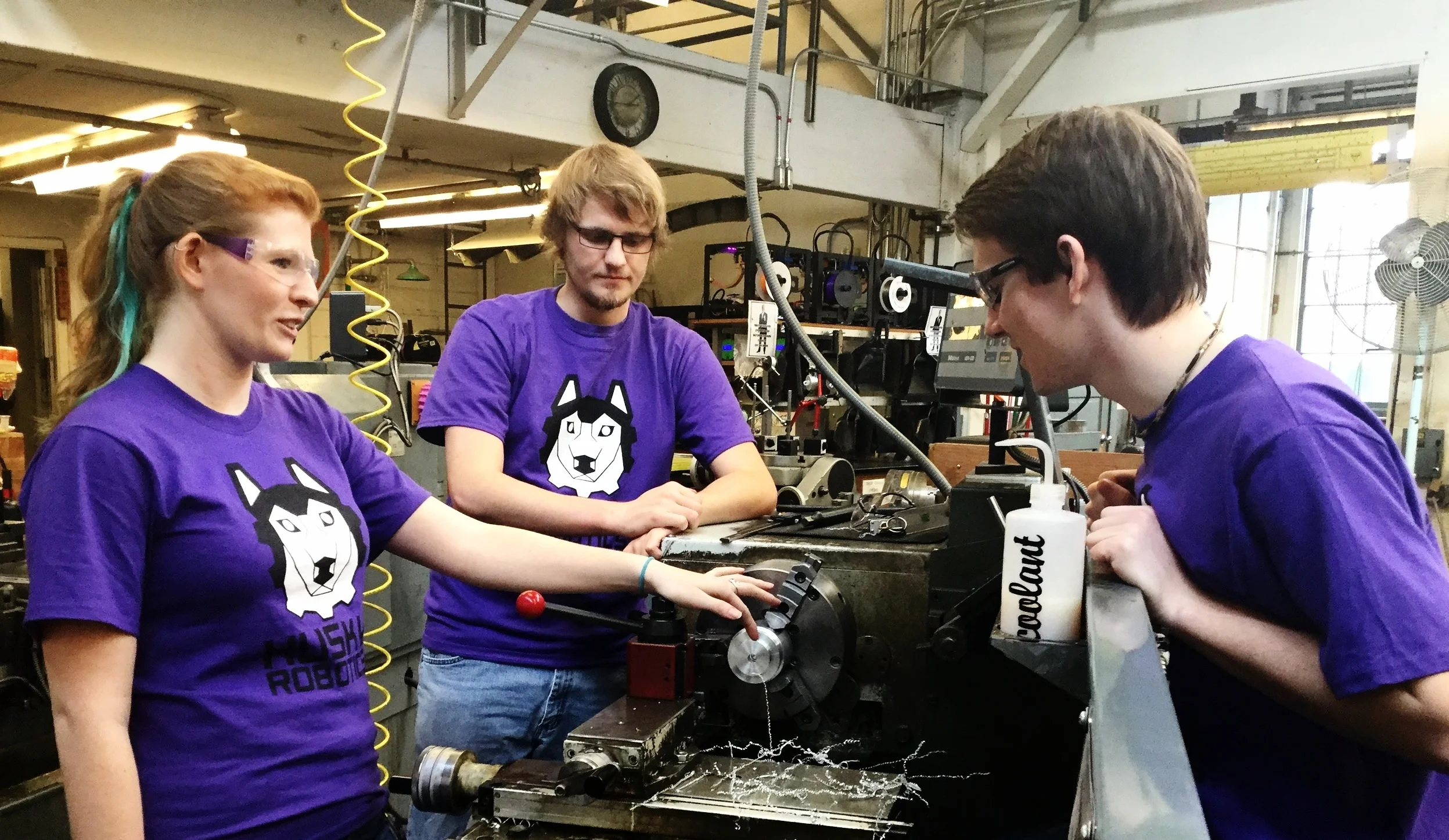

Once the rover is designed and passes internal reviews, the manufacturing team forms out of members from the primary subsystems to produce the rover components. Husky Robotics members are certified for the Mechanical Engineering machine shop and meet regularly to ensure timely production of the chassis, arm, and science station.

Weekly Time Commitment: Varies, up to 20 hours